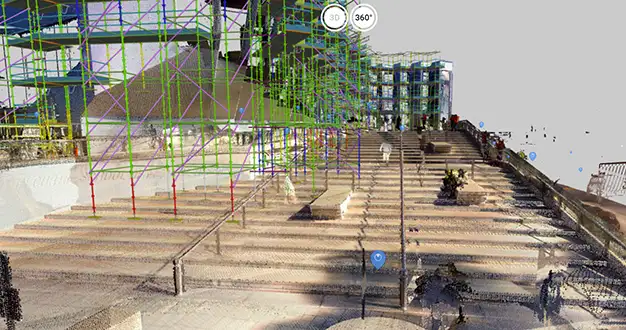

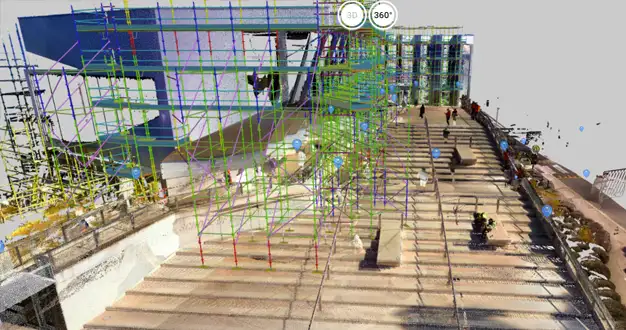

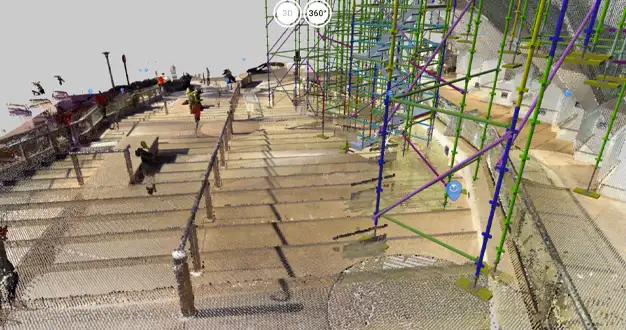

The visualisation proved invaluable. “Stakeholder engagement was incredibly quick,” said Mark. “Our clients were able to meet with everyone, walk them through the impacts on their specific areas, and adjust as needed. After just three consultations, everyone had signed off.”

Thanks to this approach, the approval process that could have taken months was completed in just three weeks. “It was a game changer for us,” Mark concluded. “The ability to show stakeholders exactly what was happening and how it would affect them helped to build confidence and trust, accelerating the process to approval.”

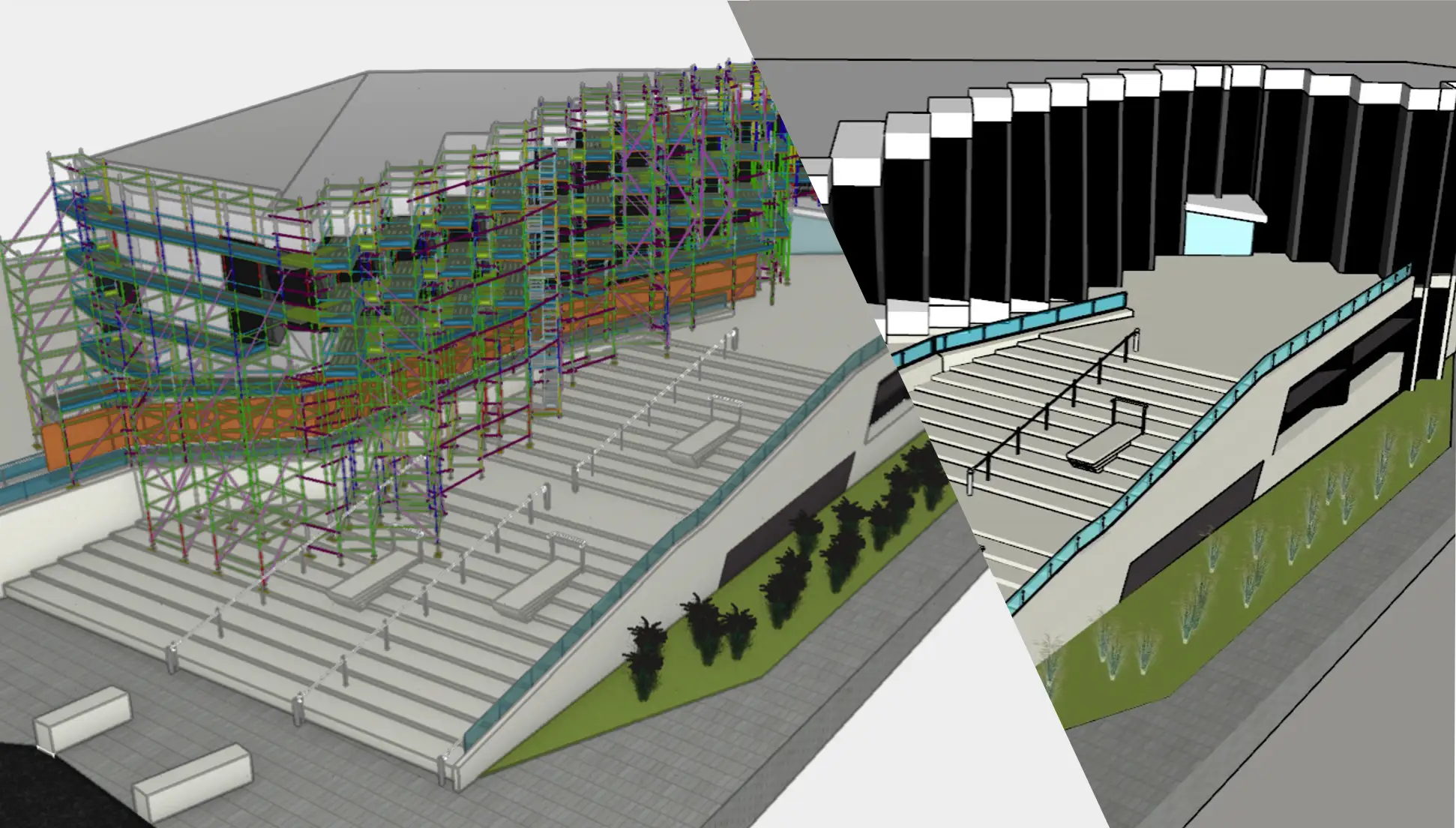

Scaffold Studio’s rapid portfolio growth is a testament to the power of visual communication in building client trust. One such example was a project for a commercial building in the Sydney CBD.

“The building management had been in discussions with the commercial tenants for over two years to arrange a compulsory replacement of flammable cladding” Mark Recalls. “The Tenants were provided rudimentary plans that created uncertainty and fear leading to delays in the project.” By presenting the information in an interactive and easy to understand 3D model, all tenants were clear on the impact the project would have on them. Sign-off for the project was obtained quickly, with no further designs required.